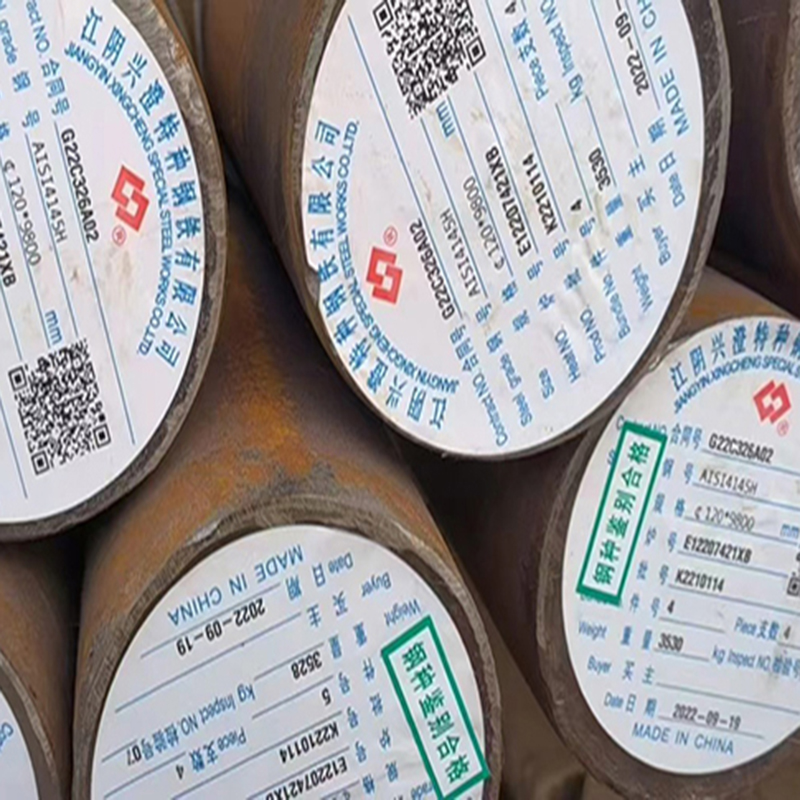

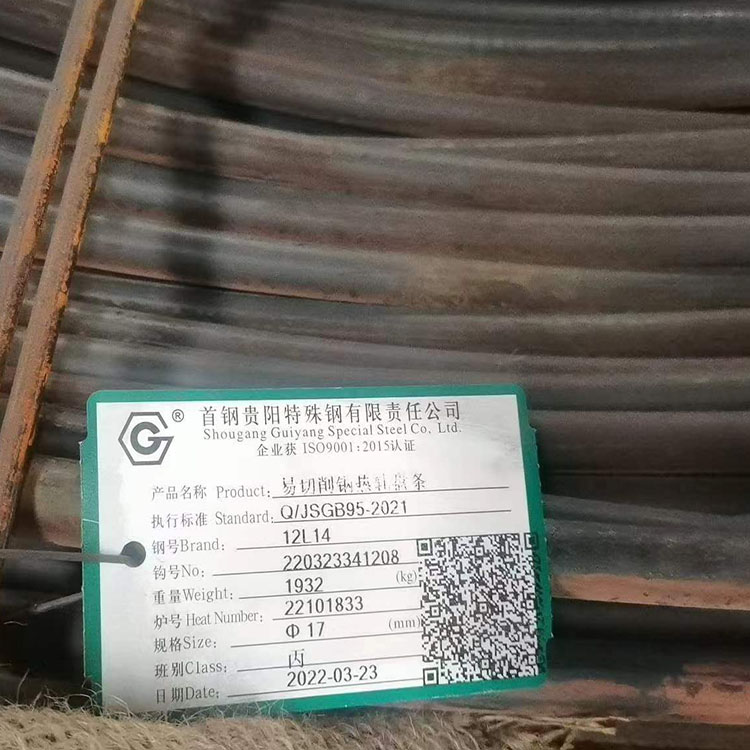

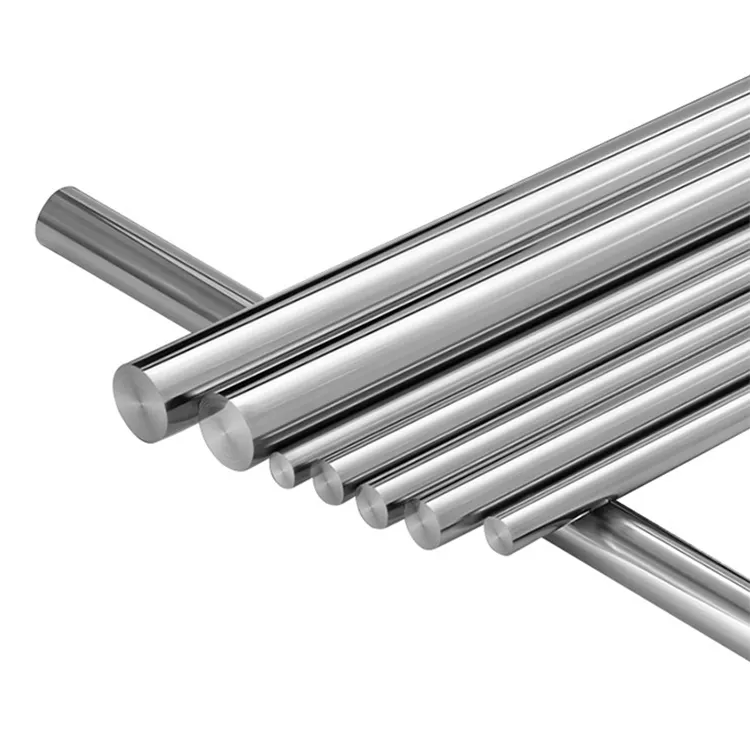

SAE4130 Zitsulo Round Bar AISI 4130 Aloyi Zitsulo Bar

Timatsata utsogoleri wa "Quality ndi wapadera, Thandizo ndilopambana, Mbiri ndiloyamba", ndipo tidzapanga ndi kugawana bwino ndi makasitomala onse a SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Tikupitiriza kusaka kuti tikhazikitse chiyanjano ndi ogulitsa atsopano kuti azipereka njira zopita patsogolo komanso zanzeru kwa ogula athu ofunika.

Timatsata mfundo za kayendetsedwe ka "Quality ndi wapadera, Thandizo ndilopambana, Mbiri ndi yoyamba", ndipo tidzapanga ndi kugawana bwino ndi makasitomala onse.Mtengo wa 4130, Tikukhulupirira kuti tikhoza kukhazikitsa mgwirizano wautali ndi makasitomala onse.Ndipo ndikuyembekeza kuti titha kupititsa patsogolo mpikisano ndikukwaniritsa zopambana-kupambana limodzi ndi makasitomala.Tikulandira ndi mtima wonse makasitomala ochokera padziko lonse lapansi kuti alankhule nafe chilichonse chomwe mungafune!

Mawonekedwe

4130 4135 4140 4145H mipiringidzo yachitsulo ndi chitsulo chochepa cha carbon alloy.Ndi a aloyi a Chrome-Molly omwe ali ndi chromium ndi molybdenum ngati othandizira.

4130 zitsulo zozungulira zozungulira zimakhala ndi luso logwira ntchito bwino, kusinthika kochepa, komanso kukana kutopa kwambiri.Ndi m'gulu la sing'anga ndi mkulu aumitsa luso zitsulo.Pambuyo pa chithandizo cha kutentha, 4140 ili ndi mphamvu zabwino komanso zonse zamakina, luso labwino, komanso zokolola zambiri.Kutentha kwa utumiki ndi 427 digiri Celsius.

4140 ili ndi mphamvu zambiri, kulimba mtima, kulimba, komanso kusinthika pakuzimitsa.Lili ndi mphamvu zokwawa kwambiri komanso mphamvu zopirira pa kutentha kwakukulu.Amagwiritsidwa ntchito popanga ma forging omwe amafunikira mphamvu zapamwamba komanso zigawo zazikulu zozimitsidwa komanso zotentha kuposa zitsulo za 4135, monga magiya akuluakulu oyendetsa magalimoto, magiya opititsa patsogolo, ma axles akumbuyo, ndodo zolumikizira ndi ma tapi a masika omwe amadzaza kwambiri.

Kufotokozera

| Dzina lazogulitsa | AISI ASTM 4130 4135 4140 Aloyi Zitsulo Bar | |

| Zakuthupi | Chithunzi cha ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6 mpaka 600 mm | |

| Pamwamba | Zopenta zakuda, Zopanda, Zopukutidwa, Zokutidwa ndi Chrome | |

| Zofotokozera | Malo ozungulira | 8mm-800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm * 4mm ~ 100mm * 100mm | |

| Malo ogona | 2 * 10mm ~ 100 * 500mm | |

| Wamakona atatu | 4 mpaka 800 mm | |

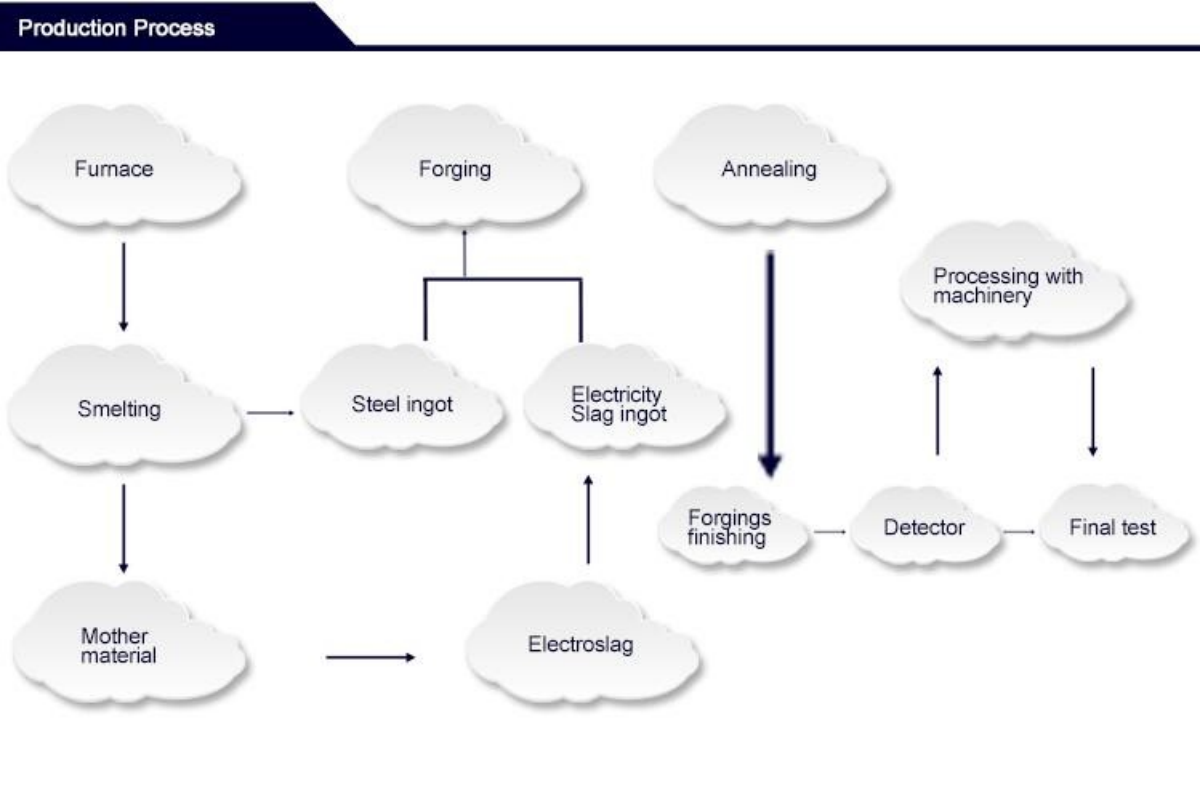

| Njira | Ng'anjo yamagetsi yosungunula, yopangidwa ndi chitsulo, yozungulira, yozungulira. | |

| Kulimba: | HBS 217Max (Yosiyana ndi chithandizo cha kutentha) | |

| Mayeso a UT | SEP 1921/84/2 C/c kalasi. | |

| Kulekerera | Dia -0/+ 0~5mm, Makulidwe -0/+ 0~5mm, M'lifupi: -0/+ 0~10mm. | |

| Utali | 2m, 4m, 5.8m, 6m, 11.8m, 12m kapena pakufunika. | |

| Phukusi | Kupaka Panyanja. | |

| Mulingo wofanana wosiyana | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | Chithunzi cha SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | Chithunzi cha SCM440 |

| 4135 | 35 Crmo | 1.7220 (34CrMo4) | Chithunzi cha SCM432 |

| 4145H | - | - | - |

Chemical Composition

| Kupanga Kwamankhwala (%) | |||||||

| Gulu | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Makhalidwe: |

| 1.Chitsulo chochepa cha alloy chokhala ndi molybdenum ndi chromium monga zolimbikitsa; |

| 2.Zabwino kwambiri pamalingaliro a fusion weldability; |

| 3.The alloy akhoza kuumitsa ndi kutentha mankhwala. |

Kulekerera

| Mkhalidwe Wotumizira |

| 1.Hot adagulung'undisa |

| 2.Annealed |

| 3.Zokhazikika |

| 4. Chotsani ndi Kukwiya |

Zinthu kutentha mankhwala

1.Annealing: 880 ℃ kuzirala kwa ng'anjo

2.Normalization: 880 ~ 870 ℃ mpweya kuzirala

3.Kuumitsa: 820 ~ 870 ℃ Kuzizira kwamadzi

4.Kutentha: 550 ~ 650 ℃ Kuzizira kofulumira

Ma Mechanical Properties amatha kupezeka ndi chithandizo cha kutentha kosiyanasiyana.

Phukusi

1.Ndi mitolo, mtolo uliwonse wolemera pansi pa matani atatu, kwa ang'onoang'ono akunja

m'mimba mwake, mtolo uliwonse wokhala ndi zitsulo 4 - 8.

2.20 mapazi chidebe muli gawo, kutalika pansi 6000mm

3.40 mapazi chidebe lili mbali, kutalika pansi 12000mm

4.Ndi chotengera chochuluka, Freight charge ndi yotsika ndi katundu wambiri, komanso wamkulu

zolemera saizi sangakhoze yodzaza mu muli akhoza kutumiza ndi chochuluka katundu

Chitsimikizo chadongosolo

1.Kukhwima molingana ndi Zofunikira

2. Zitsanzo: Zitsanzo zilipo.

3. Mayesero: Mayeso opopera amchere / Mayeso a Tensile / Eddy pano / Mayeso opangidwa ndi Chemical malinga ndi pempho la makasitomala

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Chitsimikizo

Chitsulo chozungulira cha SAE4130 ndi chitsulo chamtengo wa aloyi.Standard ASTMA29/A29M-04.Mtundu wofananira wapanyumba: 30CrMo Yogwirizana ndi mtundu waku Japan: SCM430 (SCM2) Yogwirizana ndi mtundu waku Germany: 34CrMo4 (1.7220)

4130 chitsulo structural chitsulo ali ndi mphamvu mkulu ndi kulimba, mkulu kuuma, ndi yovuta hardability awiri a 15-70mm mafuta;Mphamvu yotentha yachitsulo ndi yabwino, yokhala ndi mphamvu zokwanira zotentha kwambiri pansi pa 500 ℃, koma mphamvu zake zimachepa kwambiri pa 550 ℃;Pamene chinthu aloyi ndi pa malire m'munsi, kuwotcherera ndi zabwino ndithu, koma pamene ili pafupi malire chapamwamba, weldability ndi sing'anga, ndi preheating kuti pamwamba 175 ℃ chofunika pamaso kuwotcherera;Chitsulo chimakhala ndi makina abwino komanso pulasitiki yochepetsetsa panthawi yozizira;Pa kutentha mankhwala, pali kupsa mtima brittleness mu osiyanasiyana 300-350 ℃;Pali chizolowezi kupanga mawanga oyera.

SAE4130 zimagwiritsa ntchito makampani sing'anga-kakulidwe makina kupanga kupanga mbali kuzimitsidwa ndi kupsya mtima ndi zikuluzikulu mtanda zigawo kuti ntchito pansi pa zinthu mkulu nkhawa, monga mitsinje, spindles, ndi mawilo mkulu katundu kulamulira, mabawuti, awiri mutu mabawuti, magiya, ndi zina;Ntchito mu makampani mankhwala kupanga welded mbali, welded nyumba wopangidwa mbale ndi mapaipi, ndi mkulu-anzanu ngalande ndi kutentha osapitirira 250 ℃ ntchito sing'anga munali nayitrogeni ndi haidrojeni;M'makampani opanga ma turbines ndi ma boilers, amagwiritsidwa ntchito popanga zomangira zogwirira ntchito pansi pa 450 ℃, ma flanges ndi zovundikira za flange mopanikizika kwambiri pansi pa 500 ℃.